Temperature control in

cold rooms &

refrigerators

Cold room monitoring according to HACCP and IFS with LineMetrics

Monitoring of cold rooms

in accordance with HACCP & IFS

With LineMetrics, you can monitor your cold storage rooms and cooling appliances automatically and around the clock. You will be alerted immediately in the event of deviations. This keeps food in top quality and you comply with all HACCP and IFS guidelines.

Over 300+ companies already count on LineMetrics

Temperature monitoring requirements vary depending on the industry, internal guidelines and cooling infrastructure. But one thing always applies: manual temperature checks and records are time-consuming, expensive and incomplete. Problems are often only recognized when it is already too late and the paperwork makes it difficult to trace later.

LineMetrics supports you in your professional quality management with automated and standardized temperature monitoring. Save on personnel costs and record temperatures reliably and in compliance with the law (e.g. HACCP, GMP, EC Regulation No. 852/2004, etc.).

Challenges

- Seamless monitoring – even at night or at the weekend

- Establish traceability and fulfill legal recording obligations

- Avoid damage to goods

Your advantages at a glance

Real-time monitoring

With real-time monitoring, you retain full control at all times and can react dynamically to changes. This ensures an uninterrupted overview and the ability to respond immediately to important events.

Conformity with HACCP & IFS

Gain peace of mind both through complete documentation for audits and by ensuring that your processes comply with strict HACCPS and IFS standards.

Automatic alarms

Automatic alarms inform you immediately of critical status changes so that you can take immediate action to minimize risks and ensure the safety of your products.

LineMetrics is ideal for the following companies:

Food production

Linemetrics enables the meat industry to monitor refrigeration temperatures and environmental data to ensure product safety and quality through real-time analysis.

Food trade

Quality and safety monitoring during storage and presentation minimizes food waste and increases customer satisfaction by maintaining the cold chain.

Company restaurant

We support company restaurants by monitoring important data such as temperatures, humidity and energy consumption in real time. Efficiency increases and comfort is optimized.

Gastronomy and hotel industry

Linemetrics offers customized monitoring solutions for the hospitality industry to optimize environmental data such as temperature and humidity, save resources and improve operations.

Automate temperature monitoring and make it audit-proof

A complete solution with which the entire existing cooling infrastructure can be retrofitted.

Record temperatures

Wireless sensors with a battery life of up to 5 years can be placed in any refrigerator. They record and transmit measured values from -100° to +180° every 5 minutes.

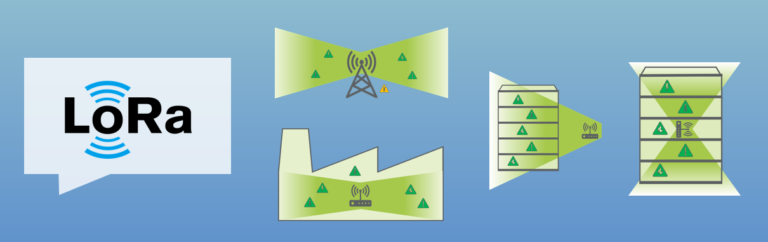

Transmit measurement data

The wireless base station (gateway) collects measurement data from up to 1,000 sensors/cold rooms throughout the building (range of hundreds of meters) and transmits it to the cloud via mobile radio.

Recording and alerting

All measurement data is stored securely and permanently in full resolution in the cloud. Individual dashboards and analyses, alerts, reports, data export and much more are easily possible.

Seamless monitoring and documentation

The values collected are recorded 24/7, stored indefinitely (including audit trail) and can be exported at any time.

Avoid damage with warning messages

Immediate alarms in the event of critical measured values or doors left open enable problems to be identified quickly.

Extreme wireless range and network-independent

Cold room walls are easily overcome. Data is sent to the cloud via mobile radio; no IT/network is required.

Sensor calibration according to current standards

DAkkS/ÖKD calibration or according to DIN EN ISO/IEC 17025 are possible for an even more precise determination of the temperature values.

Features in detail

Monitoring through sensors

Use our advanced sensor technology for seamless monitoring. Get precise insights in real time to ensure the optimal condition of your products.

Alerting in the event of deviations

Always be one step ahead with automatic alarms. If there is the slightest deviation from the ideal conditions, you will be informed immediately so that you can act quickly.

Audit-proof documentation

With real-time monitoring of cold rooms in accordance with HACCP and IFS, you have audit-proof documentation and can prove compliance with regulations at any time. One less thing to worry about, with easily accessible and detailed records.

Food trade and production

LineMetrics enables automated, HACCP-compliant recording, documentation and analysis of refrigeration temperatures and thus supports quality management processes in food retail and production. All critical control points can be integrated easily and wirelessly.

In the event of critical temperatures, an immediate notification is sent so that a timely response can also be made in the evening or at the weekend. Additional sensors warn if doors are not (properly) closed.

Company canteens, catering and gastronomy

The monitoring of critical control points as part of an HACCP-compliant QM system is often difficult to implement in catering establishments – due to the sometimes hectic operation and the lack of awareness of the problem among the staff on site.

Monitoring temperatures and doors with immediate notification of problems can take the pressure off staff, reduce paperwork and provide security during audits.

Pharmaceutical industry and laboratories

With a measuring range of down to -100°C, LineMetrics can be used for almost all pharmaceutical production processes and the storage of highly sensitive raw materials, medicines, vaccines, laboratory samples and blood products. Continuous data acquisition and storage ensures compliance with GMP guidelines and internal QM specifications.

Calibrated sensors (e.g. DAkkS), immediate alerts for critical measured values, audit trails and the monitoring of refrigerator doors help to minimize damage and liability and to impress during QM audits.

Pharmacies and pharmaceutical (wholesale) trade

LineMetrics makes it easy to ensure GDP-compliant distribution and storage of medicines and compliance with pharmacy operating regulations – both for chilled goods (2 to 8 °C) and ambient goods (15 to 25 °C). Temperature deviations are reported immediately in order to be able to react in good time. Permanent, reliable documentation supports quality management audits.

In addition to refrigerators and storage areas, loading ramps and airlocks (e.g. for night deliveries) can also be monitored wirelessly.

Logistics and refrigerated containers

The high scalability and flexibility of the LineMetrics solution enables particularly efficient use. With its enormous radio range, a single gateway can cover entire buildings, company premises or even large construction sites. Wireless sensors can then be placed anywhere and transmit the measurement data reliably.

This means that the existing temperature monitoring can be extended to additional storage areas/compartments or temperature zones, rented refrigerated containers or outdoor storage (including humidity monitoring!) at any time.

“I tested different systems.

Dirk Schwaner

None is as easy and flexible to use in the monitoring of refrigeration systems as LineMetrics.”

Managing Director | IB-Systemkälte UG – IB Systemkälte

Reliably monitor all critical control points

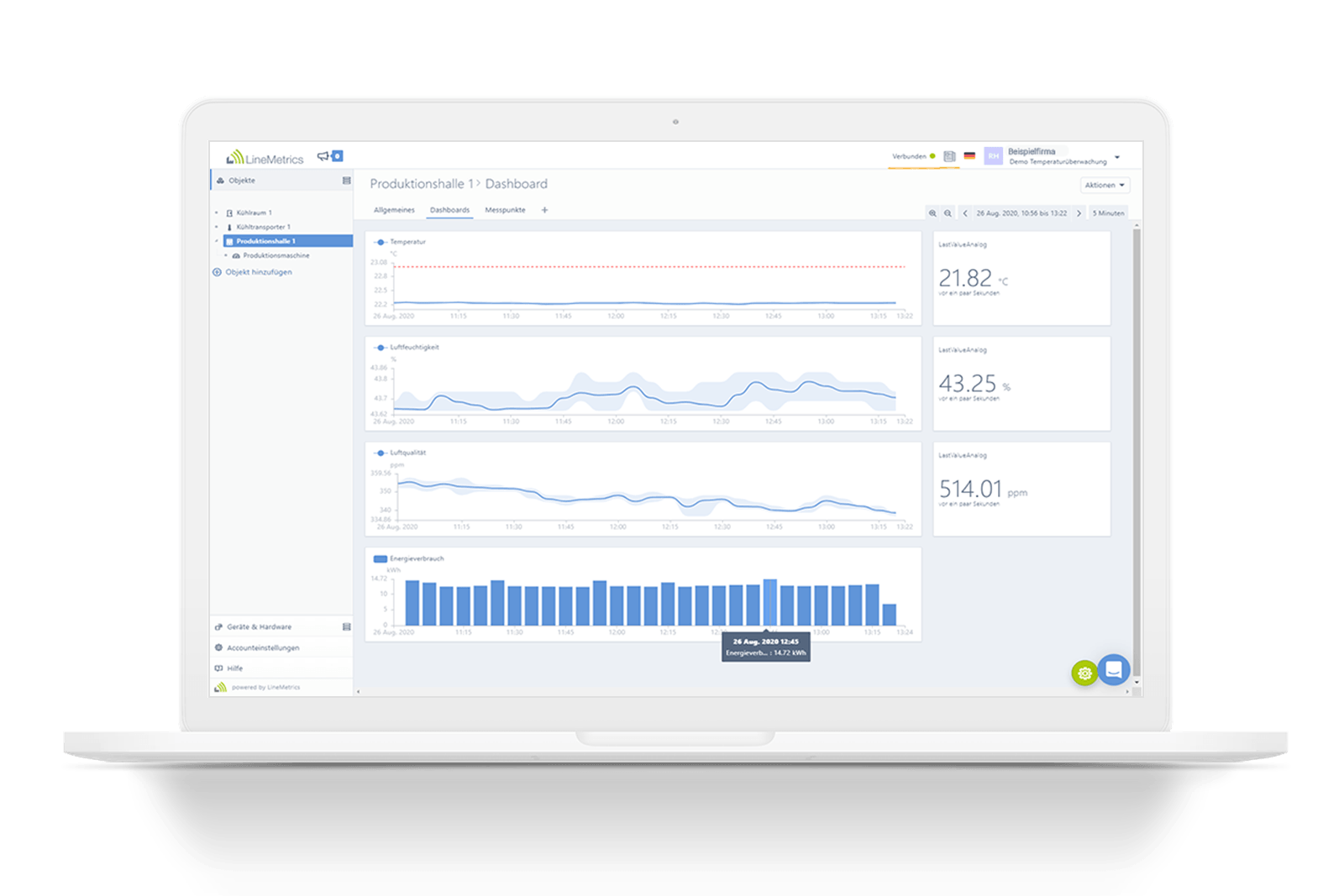

24/7 online access to current and historical measurement data – with LineMetrics (desktop & app) you are always ready for internal and external QM audits.

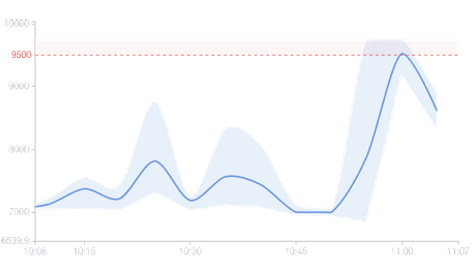

Clear dashboards that display the most important measurement data at a glance can be created individually. All measured values from the available sensors can be displayed in the form of bar/curve diagrams, dial gauges, etc. and can be combined and designed as required. Color-coded areas show immediately whether the measured values are within the desired or critical zones.

Warning messages can be created for individual ranges/limit values and provided with a trigger delay. This means that no warning is sent if critical values are only briefly exceeded. A second condition for triggering a warning can also be configured. Alerts can be sent by e-mail or SMS. The recipient, subject and message can be easily configured individually.

In addition to the online evaluation, it is also possible to automatically generate monthly reports in PDF format. These reports provide a clear summary for each measuring point on an A4 page and include a description/name of the measuring point, overview chart, statistical values (minimum, maximum, data availability, etc.), notes and audit trail.

Note important information, for example causes of deviations (“door left open” or “cooling unit failure”) and measures taken directly in the chart next to the corresponding measured value. This means that every employee knows the background immediately and the measurement data can be easily traced even years later.

Current and historical measurement data can not only be accessed online via the desktop, but also via the iOS/smartphone app at any time. The individual measuring points can be selected in the menu or simply displayed by scanning the QR code on the sensor. Ideal for employees and on-site service calls: pre-stored repair instructions, checklists etc. are also accessible via the app and enable even more efficient work.

All events (alarm messages, offline status, etc.) and changes made by users (threshold values, sensor names/locations, e-mail addresses, etc.) are permanently logged and can be found using the filter function. This makes the system and the measurement data easier to understand, monitor and fully traceable.

Flexible user authorizations enable frictionless collaboration within the team, across departments and also with external stakeholders. While administrators have all rights, normal users can only use or make selected functions and settings. Guest accounts can only call up measurement points assigned to them.

Automated algorithms continuously check the status of the monitoring solution and whether it is actually transmitting measurement data. In the event of an impairment – for example due to empty batteries, a power failure or defective hardware – immediate notification is possible. This offline alerting is freely configurable and helps to minimize any data gaps.

All measurement data and audit trails are stored permanently and tamper-proof on LineMetrics servers in German-speaking countries. This ensures that all requirements relating to storage and documentation obligations are reliably met. Irrespective of this, this data can also be downloaded at any time via data export and saved locally.

All data is encrypted end-to-end and stored and processed exclusively on multiple redundant LineMetrics servers in ISO-certified high-security data centers in German-speaking countries(more information). Furthermore, LineMetrics does not require any access to the company’s internal network. A UPS (uninterruptible power supply) can be used for self-sufficient operation during a power failure.

Gateways and certified wireless sensors for cold room monitoring

Proven hardware for precise recording and wireless transmission of measurement data, even through insulated cold room walls.

Plug & play: activation is that quick and easy

It couldn’t be simpler: no need for technicians, IT department, company network or cables. The solution is up and running within a few minutes, the first measurement data is online and warning messages for critical values are activated.

Everything included: gateways, wireless sensors, batteries, installation materials, instructions and online access will be sent to you.

Always there for you: Our Service Center is available online around the clock. You can also contact us by e-mail, chat or telephone.