Detecting unusual events with artificial intelligence

Anomaly detection is a method that uses artificial intelligence to detect even minor changes in a device or system. This makes it possible to detect at an early stage if damage is imminent in the foreseeable future. This makes it possible to avoid unplanned downtimes and schedule maintenance in good time.

Furthermore, it is possible to replace wear parts only when damage is actually apparent. In many cases, it is customary at the moment to change such parts much earlier, as there is no information about the actual condition. A significant financial advantage arises from the fact that working time and spare parts for unnecessarily early maintenance can be saved.

It is also possible to extend the intervals between checks, as (more accurate) information is available. This makes it possible to save employees’ working time.

Advantages of Artificial Intelligence in Practice

In order to provide the most practical insights into the application of the process, here is an example of a successful collaboration with a user from industry:

The user monitors a ventilation system with a vibration sensor (according to DIN ISO 10816). If the vibrations exceed a certain threshold, maintenance must be carried out.

The user has been monitoring and evaluating the data from a vibration sensor for years. As soon as the values exceed a certain threshold, he is alerted by e-mail. However, the user found that the sensor delivered implausibly low values over a certain period of time.

The reason for this ultimately turns out to be damage to the sensor. Since the values were below the threshold, no alarm was triggered, which is why the error remained undetected for a long time. If maintenance had been necessary during this time, it would not have been carried out and the device would have been damaged. The user therefore approached LineMetrics with a request for a general control of the data and a better solution.

LineMetrics decided to implement an anomaly detection system. Based on the data from a few weeks, a neural network was trained to recognize what the values of the discussed sensor typically look like. This means typical level of values, how do the values behave when the system is switched off, how do they behave when it is switched on, typical switch-on and switch-off behavior, flank heights, striking patterns, … – in short, everything that would be remembered by a person who deals with this sensor data for a longer period of time.

New incoming data is now checked to see if it is similar to the data that was used for training. If there are too many deviations, an alarm is triggered. As mentioned earlier, imagine if a human were constantly checking the data. Anything that would surprise an experienced employee about the data is also a surprise to an anomaly detection system.

In this diagram you can see the incoming measured values of the sensor, in the lower one the result of the analysis: green means that the data is OK, red means possibly erroneous data.

To validate the performance of the trained system, the data from the last two years of this sensor was reviewed. The results achieved were excellent. In addition to the known error case, it was even possible to identify several other short error cases that the user himself was not even aware of. The user fully confirmed the results obtained and has since been successfully using the system for anomaly detection in real operation.

Which measured values are particularly suitable

Basically, an anomaly detection system is suitable for monitoring many different measured values. Here are some examples for which it is particularly useful in practice to operate such a system:

- Vibrations: As mentioned above, it is convenient to perform anomaly detection for vibration measurements. Vibrations are essentially the same as the noise that a device makes, making it a very meaningful measure of the condition.

- Current consumption, especially the starting current (i.e. the current that an electric motor consumes in the first few seconds after being switched on), can also provide valuable information

- Temperature: air temperature, temperature of individual components/parts of a device, temperature of liquids

- Flow of gases or liquids through pipes

Often, useful results can be achieved when several, different measured values are monitored at the same time. Suspicious situations can sometimes only be detected by looking at different readings at the same time.

How you can benefit from artificial intelligence

Isn’t it possible to achieve the desired results by controlling multiple thresholds, slopes, pattern recognition using statistical methods, or similar concepts? – Yes, that’s a valid objection. But the big advantage of anomaly detection is that no employee has to deal with what correct data should look like in the first place. The system can be set up almost entirely automatically.

For the user in the described test case, it is very important that an unplanned downtime of the device is avoided at all costs. Therefore, employees conduct regular checks. Since anomaly detection has made the sensor data provided much more reliable, the intervals between inspections can be significantly increased in the future, which means that employee working time and thus costs can be saved.

The use case discussed here is a nice example of how a classic system, which was built from many years of experience and extensive domain knowledge and has been in use for several years, could be further improved through the application of artificial intelligence – without having to intervene substantially in the system.

Anomaly Detection vs. Predictive Maintenance

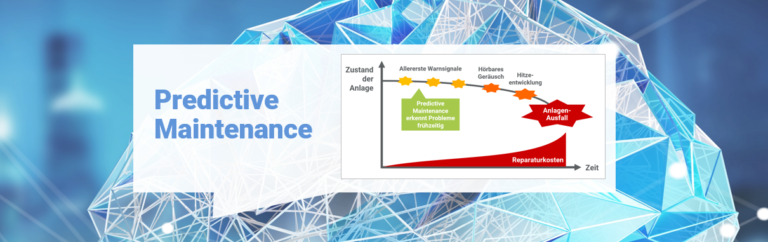

Finally, I would like to distinguish anomaly detection from another important method of applied AI, namely predictive maintenance.

An anomaly detection only detects that there are changes to the device. Predictive maintenance uses these changes to estimate how long it will take for a wear part to fail. The advantage of predictive maintenance is, of course, that more meaningful information is provided. Disadvantages, on the other hand, are that significantly more training data is required (typically several to many life cycles of a wear part), that it is time-consuming to set up such a system appropriately, and that only the condition of a single component can be monitored at a time.

As already indicated in the previous paragraph, it is an enormous advantage of anomaly detection – compared to many other AI methods – that relatively little training data is required and that it does not have to be elaborately prepared before it can be used.

Would you like to learn more about artificial intelligence in the real estate sector?

Do you have any questions about artificial intelligence in the Internet of Things? Or an exciting use case? We look forward to hearing from you.