Counselor, guardian, …? What Artificial Intelligence Brings to Smart Buildings

Artificial intelligence (AI) combined with the Internet of Things (IoT) offers enormous potential and inspires the imagination: One would often think that humans are on the verge of making themselves superfluous or even abolishing them. In practice, however, this is still a long way off – with all the positive and negative consequences.

Based on three examples from the smart building sector, we would like to explain in a practical way how artificial intelligence can be used concretely – beyond the hype – for optimization: not as a self-thinking and self-acting superbeing, but as an efficient tool that enables people to perform a variety of tasks more easily or better.

It is important for me to emphasize that it is precisely through the cooperation of humans and AI that very successful new concepts can be developed, especially in the Internet of Things.

The Indefatigable Guardian:

Anomaly detection

Artificial intelligence never gets tired, it never sleeps, it never gets bored, and it never gets sloppy. So let’s use them to monitor assets day and night.

LineMetrics uses AI to monitor the ventilation system of a large building. The behavior of the system is recorded with various sensors. For example, the power consumption of several components, the pressure in front of the filters, and vibrations are recorded. After several weeks of data collection, a neural network (in this case an LSTM = Long Short Term Memory) was trained using machine learning to recognize the normal behavior of ventilation.

This means that the neural network knows in which range current, pressure and vibrations are located when the system is switched on, in which when it is switched off, what typical behavior looks like when switching on or a typical switch-off process, or what distinctive patterns occur in normal operation.

In short, the neural network learns everything that a human would remember if they were to look at the readings of these sensors for a while.

For newly arriving sensor data, it is now checked whether it is similar to the behavior that the AI has learned through machine learning. If the deviation from the learned behavior is too great, an anomaly is detected and an alarm is triggered.

You probably know roughly what noise your car makes when everything is fine. Now, if you discover a noise that is unknown to you, you know that you should probably go to a workshop. This is pretty much the same as anomaly detection by artificial intelligence.

What are the benefits of this system?

- Small changes in the behavior of a system can provide early indications of a fault. Timely maintenance can prevent unplanned downtime.

- Artificial intelligence relieves an employee of the task of checking at regular intervals. The intervals between routine inspections can be significantly extended if detailed information about the condition of the machine or equipment is available.

- But why should we rely on artificial intelligence here? Isn’t it possible to solve such a problem with some thresholds? Yes, that’s a valid objection. However, an enormous advantage of anomaly detection by a neural network is that no one has to take the time to analyze the correct range of values of data, flank heights or other parameters and enter them into a system. The artificial intelligence learns this on its own.

The Wise Advisor:

Fault Classification

If the temperature in a cold store suddenly rises above a certain limit, it can have many causes: from an unintentionally left open door to serious damage to the cooling unit. In such a case, it is important to react very quickly and determine the cause of the temperature increase.

Fault classification or condition monitoring using AI solves this problem. A neural network can be trained in such a way that it can distinguish between several – predefined – error cases. For newly received measured values, it can then be assessed whether they can be assigned to one of the defined error cases.

Let’s use the above-mentioned comparison with a car again: If a car produces unusual noises, an experienced mechanic can often make a pretty good guess as to where the problem could be. Fault classification is exactly the same: the AI calculates a guess as to what could be the cause of an error.

What are the benefits of this system?

- If an error occurs, you can react much faster.

- Many possible error cases can be dealt with without the support of trained personnel.

- If a fault is only gradually imminent, i.e. the complete failure of the device does not occur immediately, a required spare part can still be ordered in time or the responsible technician can be called by means of fault classification.

The Far-Sighted Scout:

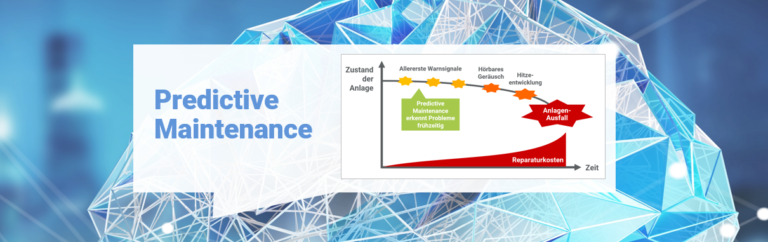

Predictive Maintenance

Until recently, in order to be able to predict the day when a consumable part would fail, you needed an experienced clairvoyant with an expensive, high-precision crystal ball. Today, artificial intelligence does this for us. Predictive maintenance, or more specifically Remaining Useful Life Estimation, has become a reality.

In the high-bay warehouse of a large, international distribution center in Germany, LineMetrics monitors the vibrations of the rollers of the storage and retrieval machines. These are the vehicles that drive through the warehouse and transport the goods. Before the system could go into productive operation, the vibrations of rollers in various wear states were recorded. With this data, a neural network, in this case a CNN (Convolution Neural Network), was trained to use the vibrations to create an estimate of when the component will have reached the end of its service life.

Think of a car again: before a wear part reaches the end of its life, it usually causes noise and vibration. An experienced mechanic can use these sounds to estimate quite well how urgently the part needs to be replaced or how long it could still be used. The AI system described works in a very similar way.

What are the benefits of this system?

- If there is no information about the actual condition of a wear part, the component must be replaced after a certain operating time (preventive maintenance). This period of time is usually set in such a way that those parts that are subjected to the greatest stress have just reached the end of their life. In practice, however, it is often the case that many components could be used for even longer.

- If the maintenance date is continuously calculated from the condition of a component, components can often be used for much longer. This saves costs for spare parts and labor.

- By continuously monitoring the condition of devices automatically, the interval between routine inspections can be significantly increased, which saves working time.

- A very important benefit of predictive maintenance technology is, of course, that unplanned downtimes of equipment and systems can be prevented and maintenance appointments can be better planned.

Which devices and systems in buildings can artificial intelligence monitor?

The following list is intended to give just a few examples of devices and systems that can be monitored by artificial intelligence. The range of possible fields of application is probably almost inexhaustible.

- everything that has to do with ventilation, blowers or air conditioning systems

- Escalators and lifts

- automatic gates and doors

- Blinds and adjustable shading

- any type of drive or electric motor

Which metrics are particularly suitable?

The same applies to suitable measured values as to the devices to be monitored: Here, too, the bandwidth is very large. The list provides only a few examples that are often used in practice:

- Vibrations and noises

- Electricity, starting current

- Pressure

- Temperature

- Flow of liquids or gases

We hope that with this article we have been able to give you some food for thought for use cases that are already feasible. Nevertheless, it is clear that the combination of smart building, facility management and artificial intelligence will produce numerous incredibly exciting developments in the coming years. We’re just getting started!